Automated Optical Positioning Helps Automate FT-IR Analysis

The incorporation of software control to infrared spectrometers and in particular infrared micro spectrometers, has provided an important capability for automated analysis. Software control of infrared optics allows methods developed by scientists to be used by less-skilled personnel or, in many cases, to be run without any operator intervention at all. Key to the development of these features is the use of compact ball slides from Del-Tron Precision, Inc., Bethel, Connecticut, that provide highly accurate optical positioning, low torque requirements and take up minimal space. This automated analysis capability recently revealed defects in a printed paper sample that could not be detected with a conventional microscope.

Infrared spectrometry utilizes electromagnetic waves to deduce the unseen details of a sample's structure and chemistry. Fourier transform infrared spectroscopy utilizes an interferometer that splits the light source into two beams that, once combined, pass through the sample. The infrared light is altered by the sample and detected. Fourier transformation of the data yields a unique spectrum, which is analogous to a "finger print" of the sample. Each spectrum can be interpreted to reveal information about the physical and chemical nature of the sample.

Analyzing trace contamination

Analyzing traces of contamination is a major infrared spectrometry application. A typical example is the identification of trace contaminants in injectable drugs. These drugs are typically purified using Nuclepore filters. In the past, particles retained on the filter were analyzed using a scanning electron microscope and energy dispersive x-ray spectroscopy. This method only identifies elements so it is useless for identifying organic or molecular compounds. Infrared spectrometry, on the other hand, is able to extract many details of the molecular structure and dynamics that make it ideally suited for identifying organic and molecular compounds.

Fourier transform infrared microscopes are one of the most popular analytical tools, because they allow samples to be examined both visually as well as in the infrared. Typically, infrared analysis is performed in either transmission (incident light passes through the sample) or reflection (infrared light is bounced off the sample, where sample spectra are also obtained) modes of operation. Sample analysis requires that component optics be accurately switched between reflection/transmission and infrared/visual modes of operation. Accuracy is critical in order to avoid spectral contamination from unwanted sample areas and attain sensitivity necessary for measuring trace components.

Major instrument advancement

Spectra-Tech, Inc., Shelton, Connecticut, and Nicolet Instrument Corporation, Madison, Wisconsin, have maintained their leadership role in infrared spectroscopy with the development of the Nic-Plan microscope, an instrument that offers the highest level of optical automation currently available. The OMNIC FT-IR software for WindowsTM that controls the operation of the unit can switch optical modes as part of a method. This makes it possible for scientists to develop methods that can later be run by technicians or operators with minimal training in operating the instrument. Mode changing can also be accomplished manually by activating a switch on the front panel of the microscope.

In designing this instrument, Spectra-Tech engineers were faced with the need to provide linear motion for mode switching optics. They needed an extremely accurate linear motion device in order to provide the precision required to achieve the highest signal to noise performance. In addition, the device had to be very small in order to fit within the tight confines of the microscope. Finally, it needed to operate with very low levels of force in order to avoid the need to increase the size of the power supply for the unit.

Accuracy in a small package

Spectra-Tech engineers selected Del-Tron N-3 ball slide assemblies because they provide high accuracy, 0.0005" per inch of travel, and repeatability of 0.0002"', making it possible to meet the critical accuracy requirements of the application.

At the same time, Del-Tron N-3 ball slide assemblies provide 2.0" travel in a package only 3.56 inches long, 0 66 inches high and 1.06 inches wide, so they easily meet the space requirements of the application. These slides also offer very low levels of torque, because the balls run exactly equal distances on the pair of tracks in linear bearings, permitting the balls to run without friction, wear, or skidding at any preload. The typical coefficient of friction for Del-Tron ball slides is 0.003. The Nic-Plan FT-IR also offers an optional motorized mapping stage that increases the level of automation by providing precise x-y positioning of the sample based on either software or joystick control. The motorized mapping stage can be used to create compositional maps of a sample without operator intervention. The software that controls the instrument makes it possible to define the entire range of motion of the motorized stage in a sample navigation window.

As a result of these improvements, the Nic-Plan microscope is considered by many to provide the most advanced technology in high performance infrared microspectroscopy. It is the only instrument currently on the market that provides fully automated software control over mode switching and sample positioning. It incorporates many advanced and patented infrared microscope features ensuring accurate microanalysis. These include on-axis optical design, redundant aperturing, targeting for the high possible spatial resolution, and sample compensation for precise focusing of the infrared beam.

Examining printed paper products

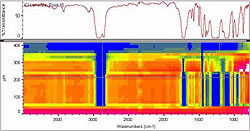

This technology was recently used to examine printed paper products. Samples were placed on a motorized stage that has positional accuracy of better than 1 micron. Z-axis positioning of the stage was obtained through an autofocus control accessory placed upon the mechanical coarse/fine control of the scope. The data collection, stage and z-axis motion were controlled through Nicolet's OMNIC software. Mapped attenuated total reflection (ATR) spectra were obtained from 4.2 by 5 0 mm square areas through repetitive sample contact with the ATR objective. The point spacing was 100 microns across the sample for a total of 2200 points.

Analysis of the spectra clearly showed the distribution of the expected species, cellulose and an amide based ink. In these spectra, cellulose was indicated by a broad absorption band centered at 1050 wavenumbers. The amide based printing ink was evident in the spectra containing the amide band centered at 1390 wavenumbers and a sharp absorption band at 867 wavenumbers. The infrared map revealed the presence of a localized defect on the surface of the print ink. Visual inspection of the sample failed to detect its presence. Quick analysis of the raw spectrum indicated that kaolinite, a common filler used in the paper manufacturing process, was present.

Spectral searching also revealed the presence of dioctyl phthalate and an aromatic acrylate, both of which are also used in paper manufacturing, but in principle were not to be present in the final product. Over the last fifteen years, the infrared microscope has evolved from a simple single function tool to a versatile accessory capable of analyzing almost any sample. The greatest benefit of infrared microscopy is the ability to spatially discriminate regions or domains within a sample. By automating optical positioning, this newest generation of instruments has the potential to dramatically reduce data collection times and allows this powerful analysis to be performed routinely.

Del-Tron Precision began operations in 1974 supplying original equipment manufacturers with the world’s first commercially available subminiature ball slide. Since then, thousands of Del-Tron ball slides have been incorporated into medical analyzing and testing machines, semiconductor processing equipment, computer peripherals, assembly systems, scientific instruments and many other machines. Del-Tron’s modern corporate campus boasts highly automated computer controlled equipment and final inspection of 100% of all products has been Del-Tron’s policy since its inception. For more information, contact Del-Tron by phone at 800-245-5013, by fax at 203-778-2721 or by email: deltron@deltron.com.