Deltron Precision's Ball Slides

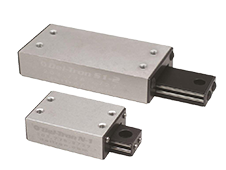

Ball slides (or ball slide assemblies) by Del-Tron Precision typically consist of a lightweight aluminum base and carriage containing two rows of precision ball bearings separated by a ball bearing retainer which rolls between four hardened and ground steel shafts on each side. Standard mounting holes are included in both the base and carriage for easy installation with only two fasteners. Their adaptable slide design allows the ball slide to be adapted to the designer's subassembly, eliminating the need for additional components and reducing both design time and tolerance buildup.

Smooth, accurate, compact, straight line design.

The straight-line design offers the lowest coefficient of friction because the rolling elements are separated from each other and they are not required to turn corners or to describe an oval path as they do in recirculating designs. The balls run exactly equal distances on a pair of tracks, permitting them to run virtually without friction, wear or skidding at any preload. The typical coefficient of friction is only 0.003. Del-Tron Precision's ball slides are available in 7 different size profiles with travels ranging from .33" to 12".

Straight-line design also allows the manipulation of preload - an important capability that is increasingly needed in modern industrial equipment design. A tool steel gib is used internally on the side of the bearing to uniformly load all the rolling elements in the bearing and reduce looseness or play. A row of staggered set screws accessible from the side of the assembly allows the preload to be set and adjusted. Available in several levels of precision, the straight line accuracies range from 0.0005"/inch in our standard units and up to .000040"/inch of travel in our high precision series.

As with many linear motion applications today, available design space continues to shrink. Engineers are constantly asked to pack more performance and technology into smaller spaces. Ball slides are the perfect solution for these applications. For instance, our C-.5 miniature ball slide is one of the smallest ever made. It is only 0.52 inches long, 0.25 inches high, 0.38 inches wide and offers a travel of 0.33 inches while providing a 0.75 pound load capacity, making it ideal for applications with the tightest envelope restrictions. Yet this assembly maintains high accuracy (0.005 inch per inch of travel runout), low friction, and stiction characteristics of Del-Tron's other ball slide assemblies.

Let us customize a ball slide to meet your application requirements.

Del-Tron ball slides are made in the USA. All modifications such as special holes, dowel pins, thread size and hole locations, etc, are done in a timely manner and in-house at our Bethel, CT factory. Special materials and coatings can be employed for cleanroom and vacuum applications as well as other sensitive applications. Our goal is to provide you with an integrated subassembly which will reduce both your labor and material costs.

Offering engineers design solutions.

- Low friction straight-line design reduces the coefficient of friction to 0.003

- Factory preload adjustment prevents side-play and backlash

- Lightweight aluminum carriage and base with high load capacity

- Built-in holes simplify installation and component mounting

- Several levels of precision available

- Easily modified to meet your applications needs, available with corrosion resistant materials

- Made in the USA

- FREE downloadable solid models are available on the Product Specification pages in Part Search

Del-Tron Precision began our operations in 1974, supplying original equipment manufacturers with the world's first commercially available subminiature ball slide. Since then, thousands of Del-Tron ball slides have been incorporated into medical analyzing and testing machines, semiconductor processing equipment, computer peripherals, assembly systems, scientific instruments and many other machines used for a variety of applications. Del-Tron's modern corporate campus boasts highly automated computer controlled equipment and final inspection of 100% of all of our products. That, as well as unmatched customer service has been Del-Tron's policy since its inception.

For more information about which Del-Tron products are right for your application, please contact us by phone at 800-245-5013, by fax at 203-778-2721, or by email at deltron@deltron.com.